At PVD Advanced Technologies Inc., ceramic coatings are applied using plasma-assisted technology to create nano-structure and nano-layer deposits.

Further improvement to the properties of hard Physical Vapour Deposition (PVD) ceramic coatings are achieved by depositing multilayers and superlattices. These are thin films formed by alternately depositing two different components to form layered structures. Multilayers become superlattices when the distance between the different layers is less than 100Å. Research has shown that multi-layered ceramic coating structures improve: hardness, toughness, wear, corrosion and oxidation resistance, in comparison to single layer applications of the same material.

Nano-Arc technology combines plasma ion-assisted and plasma arc-deposition to create high energy particles for implantation in a nano-chrystalic and multi-layered form, resulting in high density functional coatings. PVD coatings are deposited under concurrent ion bombardment. High energy ions allow for the deposition of a dense, hard film by supplying the sputtered neutrals with sufficient energy to find a suitable nucleation site, and inducing high compressive stress. PVD coatings with a hardness of 1000 – 4000HV increase the hardness of high speed steel by up to 500%.

A general purpose coating designed for moderate to high abrasion applications.

Universal high-performance coating for cutting, drilling, milling, reaming and turning. Also suitable for dry machining.

High-performance coating with high aluminum content and very high heat resistance for dry high speed machining, especially for hard machining.

Unique coating with an optimum release for forming tools, used for molds and dies, machine components, piercing and punching.

A conventional carbon nitride coating for interrupted cutting, milling, tapping, stamping, punching and forming.

A special universal coating with high hardness, heat resistance and low friction coefficient. Suitable for several applications such as milling, hobbing, tapping, stamping and punching.

A special coating for aluminum and copper cutting tools for drilling or milling.

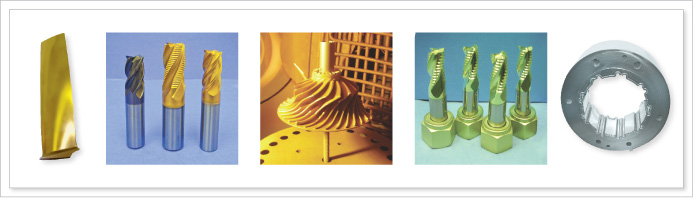

The use of PVD coating for metal cutting is one of the biggest advances in recent industry technology. This process is widely used in applications where a particularly sharp and hard cutting edge is required for optimal performance, such as drilling, threading and end-milling.

PVD coatings on cutting tools are an extremely profitable solution to increasing lifespan and productivity of materials as well as reducing costs. They:

PVD and Plasma-Assisted Physical Vapour Deposition (PAPVD) coatings, when used in the plastic tooling industry:

PVD, PAPVD and Plasma-Assisted Chemical Vapour Deposition (PACVD) coatings are used for engine, gear drives and hydraulic components to reduce friction, thereby reducing both wear and energy loss. High friction causes excessive heating, deformation of plastics, abrasive and adhesive wear (galling), and eventually seizing of tribological components. To avoid these problems, light alloy parts are coated with a high performance, low friction coating (see Diamond-Like Carbon or DLC coatings).

In addition to hardness and adhesion, PVD coatings provide a number of benefits to widely used medical devices. The most significant include:

Titanium nitride (TiN) coating is clinically being used on orthopedic implants for hip, knee, shoulder and ankle replacements as well as dental implants.

PVD coating has the capability to produce a broad sprectrum of decorative and aesthetic colour options. Titanium, Cromium and Zirconium are most coomonly used materials for decorative coatings.