Unlike chemical stripping, plasma stripping does not affect the structure of the solid carbide cutting tools after regrinding and recoating the cutting edge and rounding it within a range of 5 - 10 microns.

Plasma sharpening can prolong the lifespan of cutting blades by more than 30% the coated tool by 30% by sharpening the cutting edge within a range of 1000Å.

A conventional PVD process that is assisted by plasma generators, resulting in the deposition of a hard film with a higher density.

This process is used to increase the hardness of the substrate for tool steel, high-speed steel or solid carbide.

This multi-layered nano-structure process creates hard, anti-frictional surfaces with high erosion and corrosion protection. The coating has excellent adhesion on all materials including ceramics, glass, teflon and plastics that is impossible to achieve using other methods. Plasma-assisted deposition increases the strength of a material without affecting its hardness.

Single deposits, like TiN, CrN, TiAlN, TiAlCN, TiCN, CrCN or combinations of these, processed with plasma-assisted technology, are able to address most of the industry wear challenges. Our specialists evaluate each application and have the expertise to identify individualized client-centred solutions.

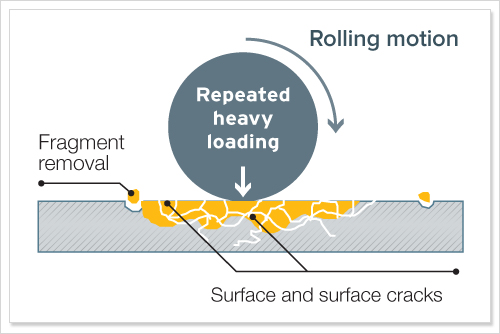

Caused by fracture or degradation in the surface.

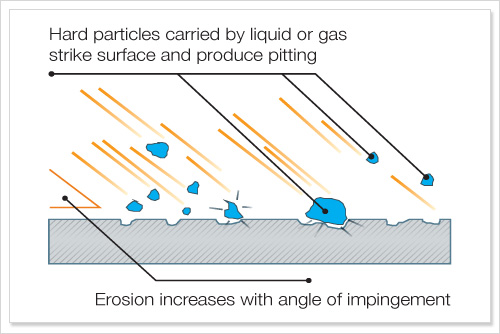

Caused by impinging particles, liquid or gas.

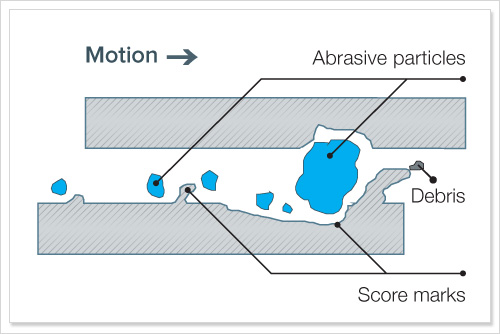

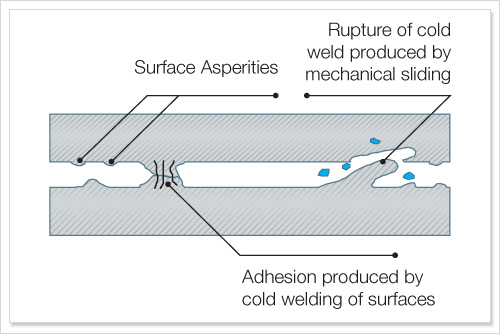

Wear from particles or protuberances rubbing the surface.

Contact bonding between two surfaces leading to loss of one or both surfaces.

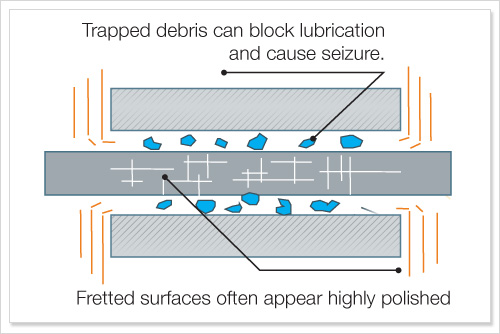

Small amplitude vibration between two contacting surface.